1) Automatic loading platform – saving loading time and labor.

2) Quick automatic workpiece positioning thanks to the laser that controls the conveyor belt.

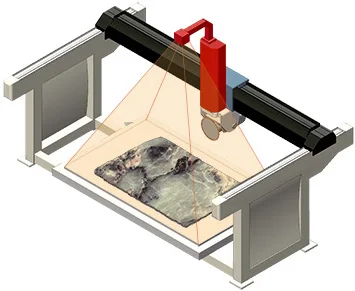

3) Slab position automatically detected by Artificial Vision.

4) Easy to program and operate – It can be programmed remotely, in advance or at the machine control in a few minutes while the machine is cutting.

4) Easy to program and operate – It can be programmed remotely, in advance or at the machine control in a few minutes while the machine is cutting.

5) Nesting software for automatic slab cutting optimization, minimize the waste and optimize the processing time.