1

/

od

6

Garnet Abrasive Recycling Removing Machine for Water Jet

Garnet Abrasive Recycling Removing Machine for Water Jet

Redovna cijena

$6,500.00美元

Redovna cijena

$6,500.00美元

Prodajna cijena

$6,500.00美元

Poštarina se obračunava prilikom završetka kupnje.

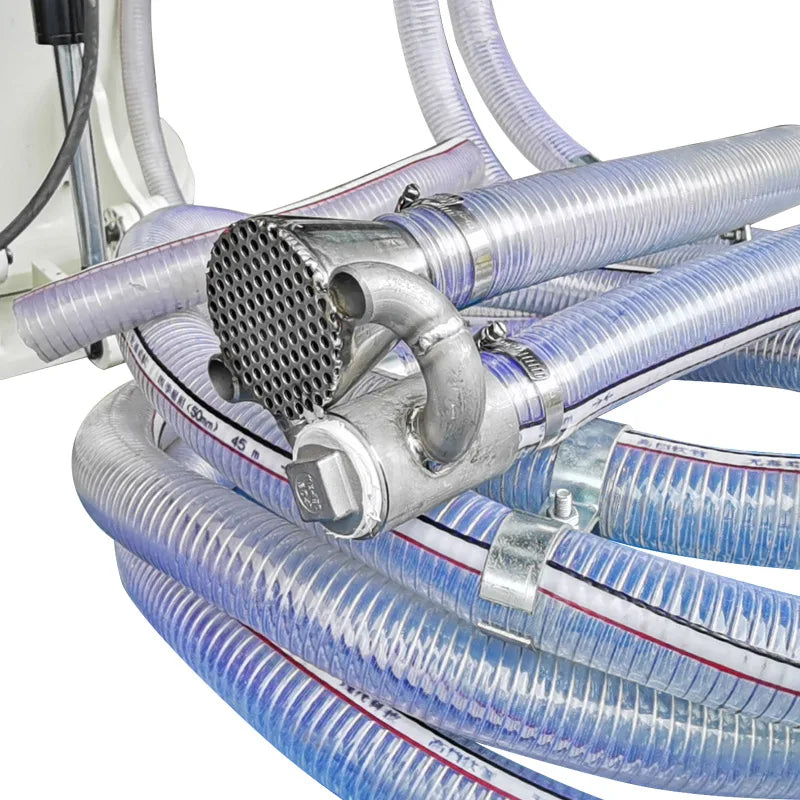

Abrasive Pumping Equipment

HLSC-046/061 Pumping Equipment with advanced water & sand separation system integrated inside, is used for clearing garnet abrasive in the water tank of waterjet machine. It doesn't disturb , doesn't need stop waterjet machine's working and doesn't need swab-off the water in the tank, just put the suction head in the water tank and begin working.

Sand removal rate: >90%

Fast clearing speed: 30-60 minutes per chamber sand if there are many sands and less mud and other impurities like plastic film, nylon mesh, in the water tank.

High capacity : 460 (610) L

Fast clearing speed: 30-60 minutes per chamber sand if there are many sands and less mud and other impurities like plastic film, nylon mesh, in the water tank.

High capacity : 460 (610) L

Easy to Operate

5 steps to finish the clearing work:

1) Equipment in place →

2) Connect air source →

3) Put the suction head in the water tank →

4) Switch on air source and pump sand →

5) Shutdow while the sand chamber is full and dump the sand wasted.

Powerful and Stable

The equipment uses an advanced pneumatic diaphragm pump to generate a constant flow of high-pressure water

under the drive of high-pressure gas. It provides powerful power for the sand removal.

Energy Saving

under the drive of high-pressure gas. It provides powerful power for the sand removal.

Energy Saving

No waste of water resource. No water loss during the sand removal process.

Mobile Flexibility

Convenient to move by forklift. One sand removing device can serve for multiple waterjet machines.

|

TECHNICAL DATA

|

|

|

|

|

Model No.

|

|

HLSC-046

|

HLSC-061

|

|

Capacity

|

L

|

460

|

610

|

|

Diameter of tank

|

mm

|

630

|

720

|

|

Height

|

mm

|

2100

|

2100

|

|

Diaphragm pump flow

|

m3/h

|

20.4 (340L/min)

|

20.4 (340L/min)

|

|

Sand pumping flow

|

m3/h

|

0.45

|

0.45

|

|

Weight

|

kg

|

460

|

530

|

Different sizes and configuration are customizable

Abrasive Screening System (Optional)

Last Chance Sifter Assy - Purifying waterjet abrasive, virtually eliminates abrasive feed tube and mixing tuble clogs due to foreign particles /debris entering into the main abrasive hopper when loading the cutting media.

Save time, money, material, reduce the amount of scrap/reworked parts and reduce machine downtime.

Količina

Učitavanje dostupnosti preuzimanje nije moguće