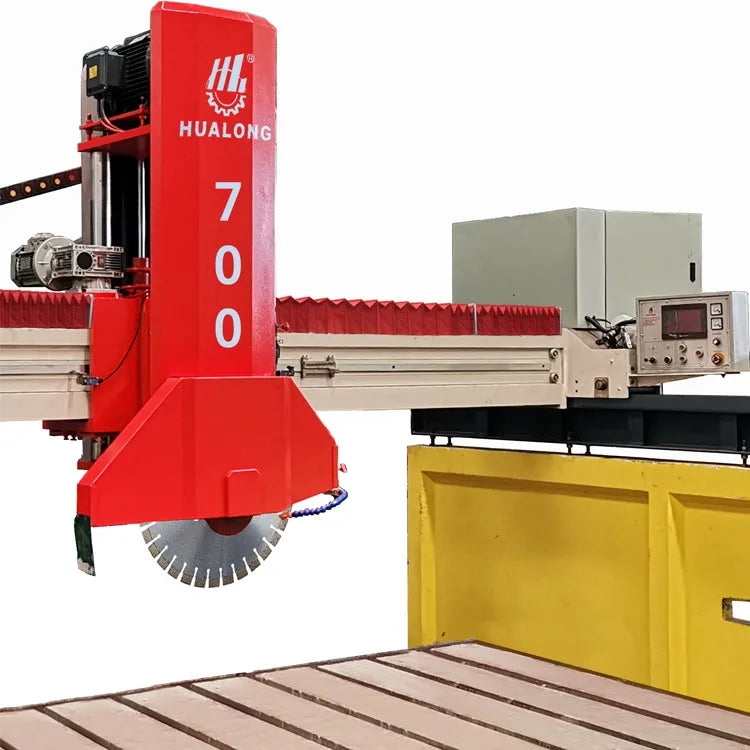

Stone Granite Marble Bridge Saw Cutting Machine for Slab

Stone Granite Marble Bridge Saw Cutting Machine for Slab

Normál ár

$17,000.00美元

Normál ár

$17,000.00美元

Akciós ár

$17,000.00美元

A szállítási költséget a megrendeléskor számítjuk ki.

- Type : Stone Cutting Machine

- Use : granite, marble slab cutting

- Production Capacity : High

- Place of Origin : Fujian, China

- Brand Name : Hualong

- Power : 30.9kw (gross)

- Dimension(L*W*H) : 600x500x280cm

- Weight : 600 kg

- Warranty : 1 Year

- Key Selling Points : Easy to Operate

- Cutting thickness (max) : 220mm

- Machinery Test Report : Provided

- Video outgoing-inspection : Provided

- Core Components : Bearing, Pump, Gearbox

- Blade diameter : 400-700mm

- Working platform dimensions : 3200x2000mm

- Max. processing dimensionss : 3200x3200x220mm

- Working platform tilting degree : 0-85°

- Working platform rotating degree : 90-360°

- Power of main motor : 18.5kw

- Water consumption : 4 m3/h

- Showroom Location : None

- Condition : New

- Marketing Type : Ordinary Product

- Warranty of core components : 6 Months

- Applicable Industries : Stone Processing

Infrared Automatic Bridge Stone Cutting Machin

HLSQ-700 is mainly used for granite, marble cutting, with many advantages such as rational construction, steady movement, high accuracy, convenient installation and maintenance. Compared with similar products, the advantages are obvious. It is a very important and common equipment in stone processing equipment.

Main Features

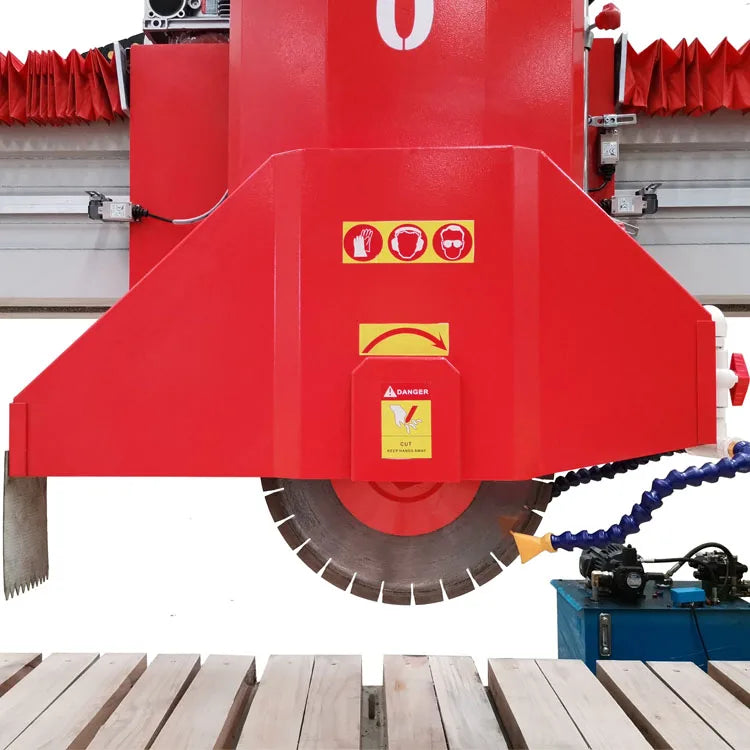

1) Controlled by PLC, operated expediently, accurately and stably.

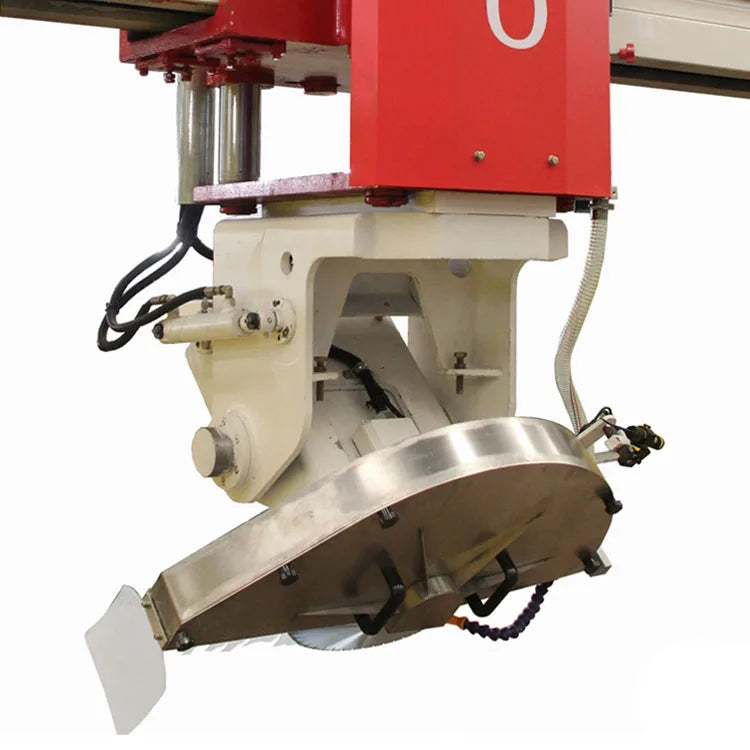

2) Cutting head can tilt 45° for mitre cuts (Optional function).

3) Working table can tilt at 85 degrees for easy loading slabs and rotates 360 degree for ideal cutting. A full 360°

rotating table enables precision cutting of material edges.

rotating table enables precision cutting of material edges.

4) Laser device is adopted for slab positioning accurately.

|

TECHNICAL DATA FOR HLSQ-700

|

|||

|

Configuration

|

Diameter of blade

|

mm

|

Φ400 - 700

|

|

Power of main motor

|

kw

|

18.5

|

|

|

Working platform dimensions

|

cm

|

320 x 200

|

|

|

Main Performance Parameters

|

Max. processing dimensions

|

mm

|

3200 x 3200 x 220

|

|

Working platform tilting degree

|

n°

|

0-85

|

|

|

Working platform rotating degree

|

n°

|

90-360

|

|

|

Water consumption

|

m3/h

|

4

|

|

|

Measurement

|

Gross weight

|

kg

|

6100

|

|

Dimension (L x W x H)

|

cm

|

600 x 500 x 280

|

|

Advantages

1) Durability:

Good quality steel is used as the mechanical parts and reliable electric parts are used to guarantee high reliability & durability.

2) Precision: a, Crossbeam movement (Y-axis) along V-guide way with high precision.

b, Magnetic ruler is adopted for slicing measure. c, Laser device for accurate alignment. d, V-guide rail system applies not only in left and right movement of the girder but also in lifting up and down section, thus reduces the error and improves cutting accuracy.

3) Use-friendly: a, Touch screen control panel and all movement is controlled by PLC to realize operation available.

b, Work table can be tiltable and removable.

Mennyiség

Nem sikerült betölteni az átvehetőségi adatokat