HUALONG MACHINERY Multi Wire Saw Machine For Granite

HUALONG MACHINERY Multi Wire Saw Machine For Granite

multi wire saw machine for granite

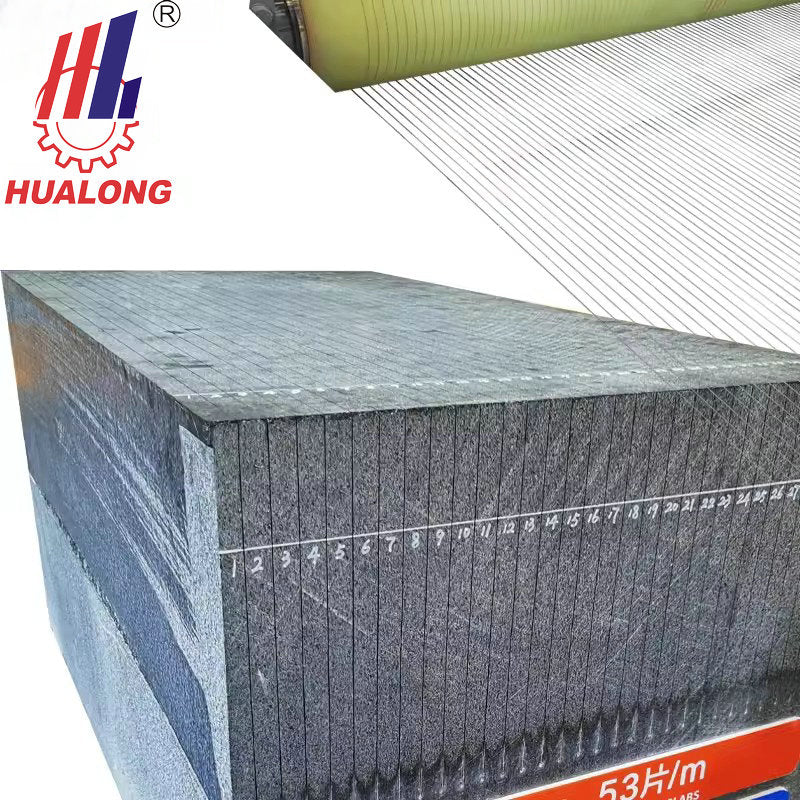

The wire saw, also known as the "diamond multi-wire cutting machine," is a large equipment designed for cutting and processing both natural stone and artificial granite. It uses a diamond wire that moves either in a single direction or back and forth to make cuts. This method creates narrower cuts than traditional gang saws, resulting in better material efficiency and reduced energy use.

The HLMW-100/150 greatly enhances productivity in the stone cutting process. When compared to traditional machines like gang saws and multi-wire saws, it boosts production levels remarkably. By utilizing ultra-thin diamond wire for slab cutting, the HLMW-100/150 can create at least 16% more slabs than gang saws and 20-25% more than standard multi-wire saws that use thicker diamond wires. This model not only increases the number of slabs generated from each block but also elevates the overall efficiency of the cutting operation. This improvement is crucial for high-cost stone, where each additional slab contributes significantly to profits. The economic advantages are considerable.

Is the diamond wire of your machine easy to break?

No, that's not correct at all. The issues stem from older machine models.

Thanks to our advanced patented mechanical design and innovative winding methods, the diamond wire won't snap due to stones.

For stones rated with a Moh's hardness of 7 or below, our diamond wire cuts smoothly and operates steadily without breaking.

In contrast, stones harder than a 7 are a challenge for the diamond wire at this time. Although the diamond grit on the wire may wear down quickly, the wire itself won't break.

If the wire does break due to some external force accidentally, the solution depends on where it snapped. Cutting can be resumed in a timeframe of 0.5 to 5 hours.

One important aspect of the HLMW-100/150 is its focus on environmental sustainability. With its extremely thin diamond wire, the machine significantly cuts down on the production of stone dust and mud while cutting. Compared to gang saws, stone dust emissions are lowered by at least 16%, and for older multi-wire saws, by 30-35%. This waste reduction helps create a cleaner workspace. Additionally, less sludge and debris help prolong the lifespan of the water filtration system.

Furthermore, the HLMW-100/150 stands out for its energy efficiency. It uses around 40-45 kWh of electricity each hour, which is considerably less than the 80 kWh that traditional gang saws require. This lower energy use not only decreases operating expenses but also enhances the economic advantages for stone processing facilities.

The HLMW-100/150 is known for its exceptional cutting accuracy and flexibility. This machine can slice ultra-thin slabs down to 10 mm and maintains a thickness tolerance of ±0.3 mm, which means there's often no need for complex finishing, reducing further processing.

Additionally, the HLMW-100/150 has a compact design that requires over 30% less floor space compared to standard gang saws. Such a layout helps stone processing facilities utilize their workspace more effectively, making it easy to set up in the limited areas of smaller workshops.

| Technichal Data for HLMW-100/150 | ||

|

Diameter of diamond wire |

mm |

0.3 - 0.8 |

|

Max. volume of wire stored |

km |

30 / 50 |

|

Operating line speed |

m/s |

25 - 40 |

|

Thickness of slabs cutted |

mm |

5 - 30 |

|

Max. number of cutting pieces |

piece |

100 / 150 |

|

Max. processable size of block |

mm |

3500x2100x2000 |

|

Max. spindle speed |

rpm/min |

3000 |

|

Main motor power |

kw |

60 |

|

Gross power |

kw |

453 |

|

Dimensions (LxWxH) |

mm |

10000x4500x7000 |

In the industry, diamond wire has been utilized in primary sawing for several years. This wire is attached to well-known machines that typically consist of two pulleys, creating a loop that cuts through stone blocks.

Recently, there has been a rise in machines equipped with multiple diamond wires, which are placed on multi-channel drums or composed of several pulleys. These machines allow for several simultaneous cuts on stone blocks, significantly increasing production efficiency.

However, the machines used until now have faced various technical issues, particularly regarding the proper tensioning and control of the wire loops. Additionally, a major challenge has been the difficulty in easily adjusting the positions of wire pairs to achieve different thicknesses for the produced boards.

Our machine addresses these challenges effectively. It features a straightforward individual tensioning device for each tension wheel, making it easy to adjust the processing thickness of the slabs and boards being cut.

Impossibile caricare la disponibilità di ritiro