1

/

из

6

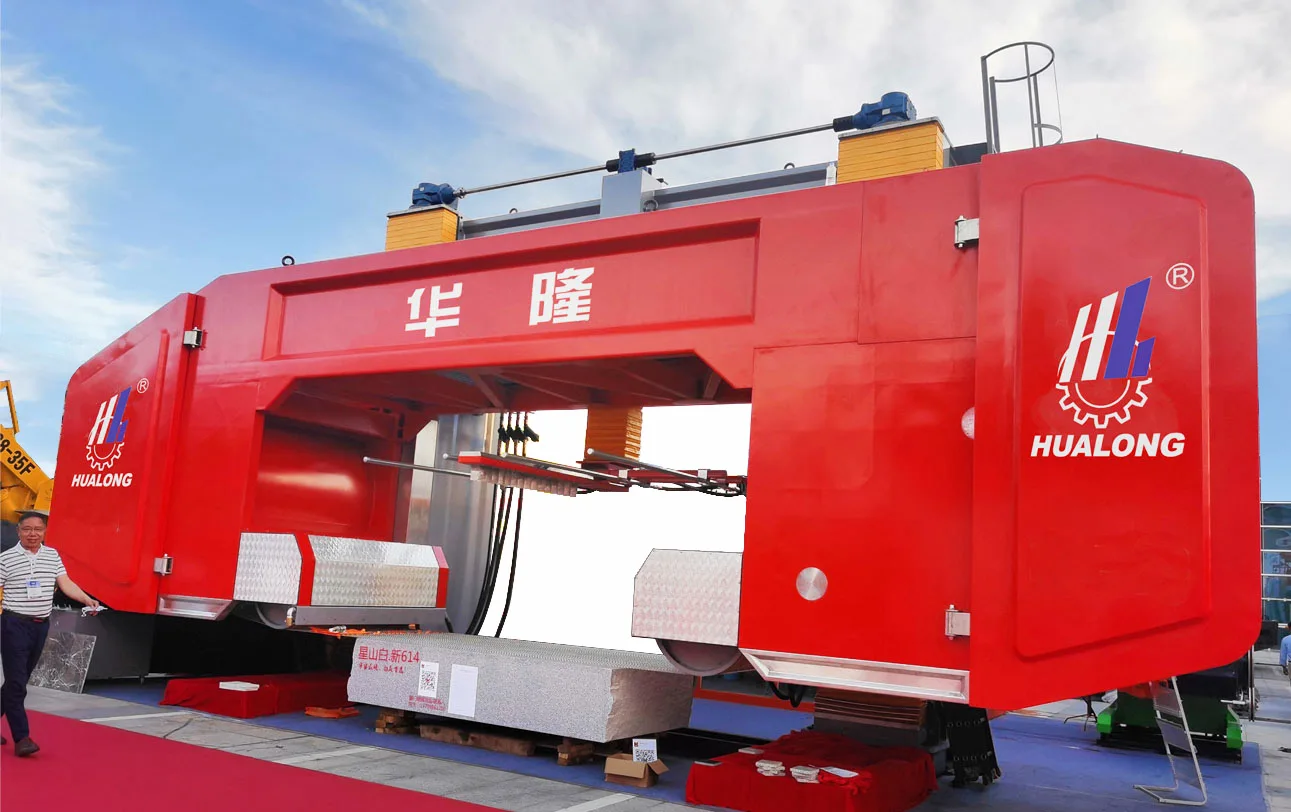

Hualong Machinery Pavoni Structure PLC Digital Control Multiwire Multi-wire Diamond Multi Wire Saw Marble Granite Stone Cuttin

Hualong Machinery Pavoni Structure PLC Digital Control Multiwire Multi-wire Diamond Multi Wire Saw Marble Granite Stone Cuttin

Обычная цена

$200,000.00美元

Обычная цена

$200,000.00美元

Цена со скидкой

$200,000.00美元

Стоимость доставки рассчитывается при оформлении заказа.

Multi Wire Saw Machine

HLMW series Multi Wire Saw for granite cutting is a technology developed for the enhancement of productivity in the granite gangsaw industry, with saving on the cost of raw material sawn to the tune of 3% on an average of a granite block sawn..

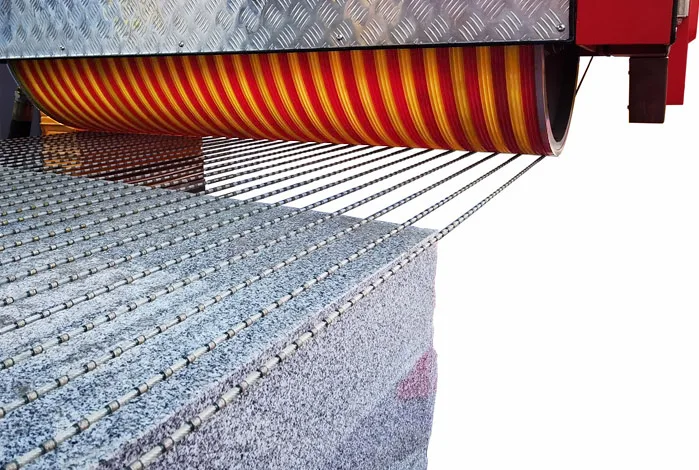

It cut the granite block with a number of diamond wires. The diamond wire is a cable with a diameter of 6.3-7.2 mm and on its surface are threaded diamond-impregnated beads. The diamond beads serve as an abrasive and are cooled and cleaned by water jets, the wasted material is also eliminated by the water.

The Multi Wire Saw enables better surface finish on the slab sawn & the biggest advantage is the low sawing cost. Further, there is an excellent cutting quality with accuracy and smooth cutting with low noise. There is also a good amount of saving on the power & water consumption.

Main Features

* Sturdy construction

* Easy cutting* Corrosion-resistance

* Quick and precise cutting

* Available for different size cutting of slab

* Perfect surface of the slabs

* Fast and easy wire change and positioning

* Relaible and with minimal operating costs

* Less water consumption and low cutting noise

Requirements:

* Square block

* Gang saw size block properly cemented on trolley

* Availability of water as the coolant.

Requirements:

* Square block

* Gang saw size block properly cemented on trolley

* Availability of water as the coolant.

|

TECHNICAL DATA

|

|

|

|

|

|

|

Model No.

|

HLMW-21U

|

HLMW-36U

|

HLMW-42U

|

HLMW-58U

|

HLMW-72U

|

|

Max. Number of Wire (pcs)

|

21

|

36

|

42

|

58

|

72

|

|

Length of Wire (m)

|

23

|

23

|

23

|

23

|

23

|

|

Diameter of Wire (mm)

|

6.3/7.2

|

6.3/7.2

|

6.3/7.2

|

6.3/7.2

|

6.3/7.2

|

|

Slab Thickness (mm)

|

20/30

|

20/30

|

20/30

|

20/30

|

20/30

|

|

Max. Cutting Length (mm)

|

3200

|

3200

|

3200

|

3200

|

3200

|

|

Max. Cutting Height (mm)

|

2000

|

2000

|

2000

|

2000

|

2000

|

|

Max. Wire Tension (kgs)

|

200/250

|

200/250

|

200/250

|

200/250

|

200/250

|

|

Wire Speed (m/s)

|

0-35

|

0-35

|

0-35

|

0-35

|

0-35

|

|

Main Motor (kw)

|

95

|

132

|

160

|

250

|

280

|

|

Water Consumption (L/min)

|

500

|

800

|

1000

|

1800

|

2300

|

|

Machine Length (mm)

|

11000

|

11800

|

11800

|

11800

|

11800

|

|

Machine Height (mm)

|

5900

|

5900

|

5900

|

5900

|

5900

|

|

Gross weight (kg)

|

30000

|

35000

|

45000

|

50000

|

65000

|

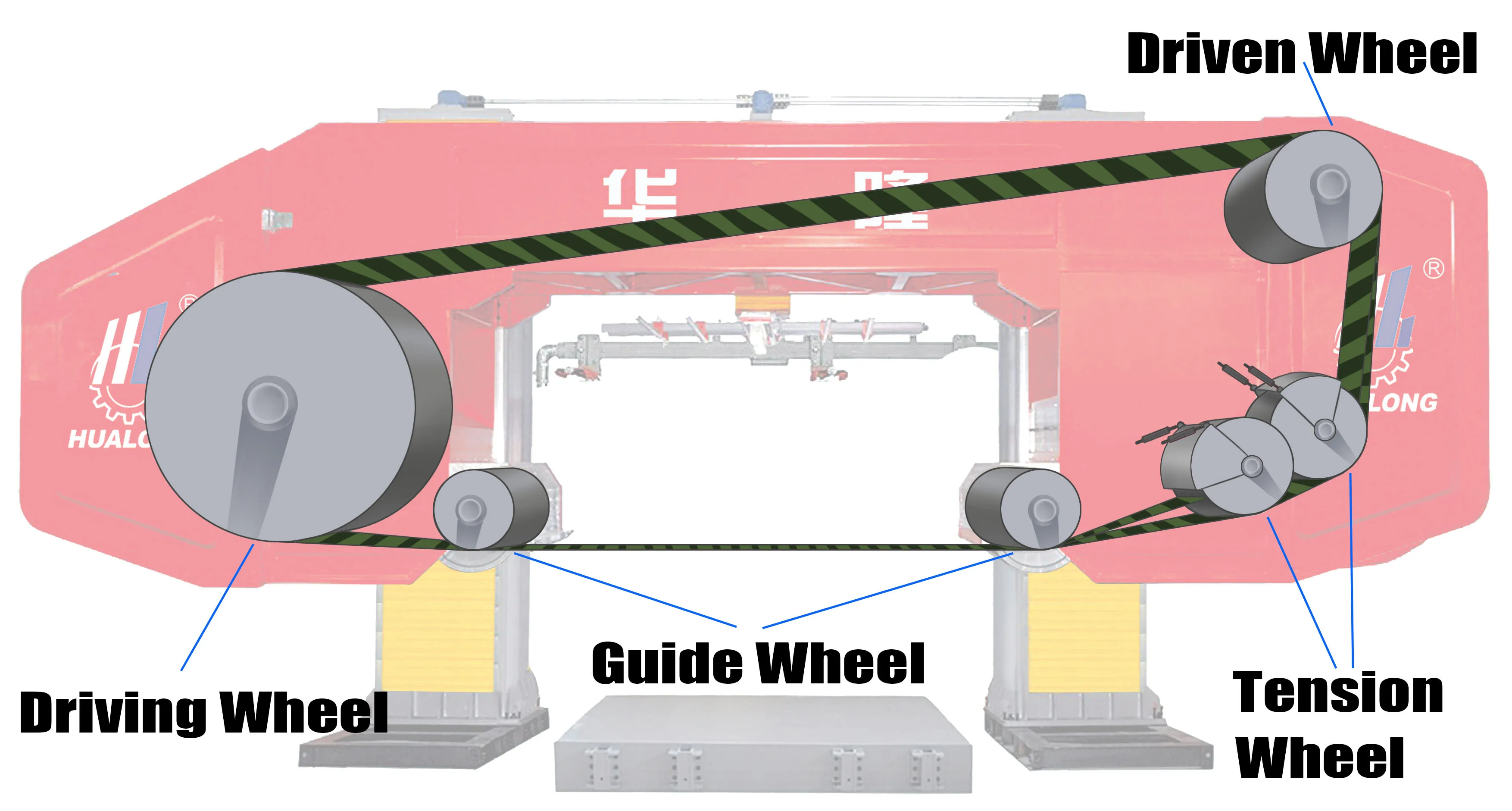

Main Components of the Multiwire Machine HLMW series:

* Driving system,

* Tensioning system,

* Trolley moving system,

* Speed and pressure regulator system,

* Sprinkler system,

* Lubricating system

Super stable structure of HUALONG multi wire saw same as Italy Pedrini

Sawing quality and productivity are unparalleled while sawing structure feed rates remain consistently at the maximum possible levels

Allows cutting several blocks of different dimensions and stone types simultaneously. Greater cut capacity using less space and less cost.

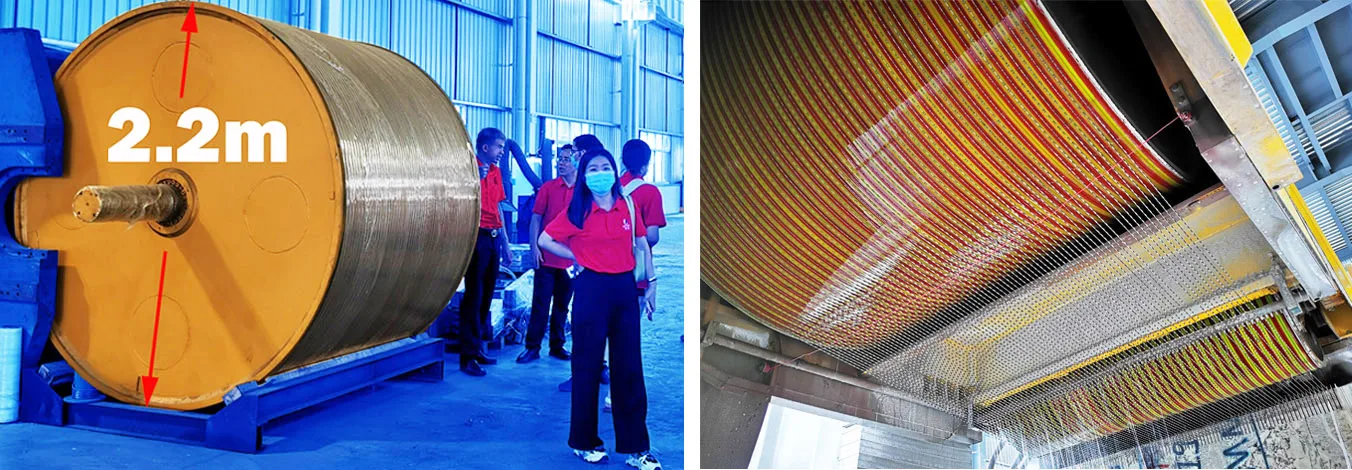

Driving Wheel

An enormous roller with a diameter of 2,20 metres and a peripheral speed of 35 m/s.

The surface of the wheel is inlaid with a wear-resistant polyurethane rubber liner (dovetail groove) which is convenient for users to replace and maintain. So it reduces the maintenance cost.

Wire Guide Rollers

Each guide wheel can approach the block and always assume a position in its immediate vicinity. So as to guarantee the highest rolling speed and the greatest cutting precision, resulting in a better final quality of the cut slabs.

Individual wire tensioning

The system performs the displacement necessary for diamond wires replacement, for slabs thickness change, holds programmed tension equal on each wire and balance wire elongation during the cut. The tensioning pulley of each wire is constantly controlled. The machine is able to check the eventual excessive stretching of each wire.

Supported on 2 columns

The structure of two columns

strongly fixed to foundations and one connecting "W" structure, that have been built with wide closed section in large thickness normalized steelwork. All the structural parts have undergone structural checks in accordance with FEM (Finite Elements Methods).

strongly fixed to foundations and one connecting "W" structure, that have been built with wide closed section in large thickness normalized steelwork. All the structural parts have undergone structural checks in accordance with FEM (Finite Elements Methods).

It ensures a high level of rigidity and no vibration.

Water supply on top & both sides

Compared with the traditional granite cutting by gang saw, less water consumption is needed.

Water jets cool and clean the diamond beads, and eliminate the wasted material also.

Water jets cool and clean the diamond beads, and eliminate the wasted material also.

Control Cabinet

Split-type electric control cabinets with Immediate and intuitive touch screen operator interface for machine management. Among them, the main control cabinet is for controlling the main motor driving, diamond wire saw cutting speed adjusting etc. This design makes the operation more easily.

* Colour can be customized

* 10, 21, 36, 42, 58, 72, 80, 82, 84 or 86 wires can be customized

Thanks to a series of ladders and platforms, operators can perform wire changeover and repositioning operations rapidly and easily.

Количество

Не удалось загрузить сведения о доступности самовывоза